When it comes to protective coatings, Raptor Liner has etched its name as a premier choice for durability and resilience. Yet, a common query echoes among DIYers and enthusiasts alike: Is there a reliable substitute for the Raptor Liner hardener? In this in-depth exploration, we will navigate the intricate landscape of protective coatings, unraveling alternatives, their applications, and the strategies to achieve outstanding results.

Understanding Raptor Liner and Its Hardener

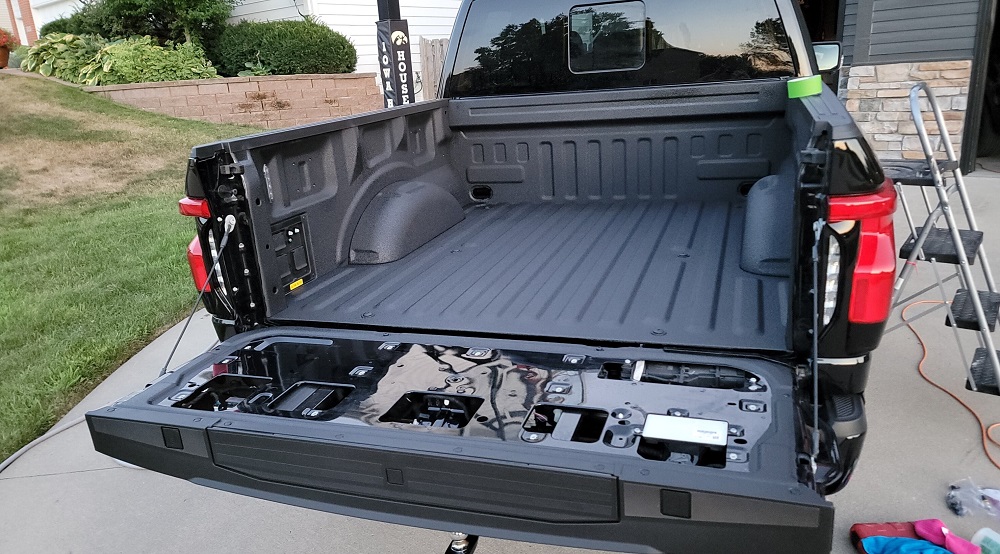

Before delving into substitutes, let’s establish a foundational understanding. Raptor Liner stands out for its robust polyurethane coating, finding widespread use in truck beds, off-road vehicles, and various industrial applications. The hardener, a pivotal component, contributes significantly to the coating’s strength and longevity, creating a formidable protective shield.

Why Seek a Substitute?

1. Cost Considerations

In an era of escalating product costs, the quest for a cost-effective alternative gains prominence. We’ll explore substitutes that not only deliver comparable performance but also offer an economical edge without compromising quality.

2. Availability and Accessibility

Navigating the world of coatings can be daunting, especially when regional limitations or supply chain disruptions hinder access. Our journey will lead us to alternatives that are more readily available, ensuring a smoother project execution without sacrificing quality.

Exploring Raptor Liner Alternatives

3. U-POL Raptor Liner

One of the prominent contenders in the alternative arena is U-POL Raptor Liner. Drawing parallels with the original, we’ll dissect its composition, application process, and delve into user experiences to provide a comprehensive overview.

4. Al’s Liner

For those inclined towards a DIY-friendly approach, Al’s Liner emerges as a noteworthy polyurethane alternative. Our exploration will uncover its features, potential drawbacks, and practical applications, offering insights for the hands-on enthusiast.

DIY Solutions and Homemade Alternatives

5. Epoxy Resin and Polyurea Blends

Crafty DIYers often experiment with epoxy resin and polyurea blends, creating unique formulations. We’ll explore the possibilities, detailing the composition, application techniques, and real-world outcomes of these intriguing homemade substitutes.

6. Linseed Oil-Based Coatings

For the environmentally conscious DIYer, linseed oil-based coatings present an eco-friendly substitute. Delve into their composition, application methods, and assess how they measure up against the stalwart Raptor Liner.

Tips for Successful Substitution

7. Compatibility Testing

Embarking on the substitution journey requires careful consideration. We’ll guide you through compatibility testing, ensuring your chosen alternative seamlessly integrates with your project for optimal results.

8. Application Techniques

The art of coating application varies among different products. Discover the best practices for applying Raptor Liner substitutes, understanding the nuances that can make a significant difference in the final outcome.

User Experiences and Reviews

9. Testimonials from the Community

Real-world experiences provide invaluable insights. We’ll share user testimonials, offering a nuanced perspective on successes, challenges, and practical tips for a successful substitution journey. (See Also: Can You Paint Over Raptor Liner? Tips and Tricks for a Flawless Finish)

Common Concerns and Misconceptions

10. Myth-busting the Substitution Process

In separating fact from fiction, we’ll address common concerns and misconceptions surrounding Raptor Liner substitutes. Equip yourself with accurate information to make informed decisions and dispel any uncertainties that may linger.

Exploring Additional Alternatives

11. Bedliner Sprays: Rust-Oleum vs. Dupli-Color

In our continued quest for alternatives, we’ll explore the landscape of bedliner sprays, pitting Rust-Oleum against Dupli-Color. Uncover the strengths and weaknesses of these contenders in comparison to Raptor Liner.

12. Ceramic Coatings: A High-Tech Approach

For those seeking cutting-edge solutions, ceramic coatings present a high-tech alternative. Explore their advanced features, application methods, and how they fare in the durability department.

Expert Tips: Navigating Raptor Liner Substitutes with Confidence

As you embark on the quest for a Raptor Liner hardener substitute, expert tips can make all the difference in achieving optimal results. Let’s delve into some valuable insights to guide you through the intricate landscape of protective coatings.

1. Conduct Thorough Compatibility Tests

Before committing to a substitute, conduct rigorous compatibility tests. Ensure that the alternative coating seamlessly integrates with the surface and existing layers, preventing any unwanted reactions that could compromise the final result.

2. Follow Manufacturer Recommendations

When exploring alternatives like U-POL Raptor Liner or Al’s Liner, adhere closely to the manufacturer’s recommendations. This includes precise mixing ratios, application techniques, and curing times. Deviating from these guidelines may affect the coating’s performance.

3. Prioritize Surface Preparation

Regardless of the substitute chosen, impeccable surface preparation is non-negotiable. Thoroughly clean and, if necessary, sand the surface to create an optimal bonding environment. A well-prepared surface ensures better adhesion and longevity of the coating.

4. Experiment with Application Techniques

Different coatings may require varied application techniques. Experiment with different methods, such as spraying, rolling, or brushing, to find the one that suits your chosen substitute best. The right application technique contributes significantly to the coating’s effectiveness.

5. Consider Environmental Impact

For eco-conscious enthusiasts exploring substitutes like linseed oil-based coatings, consider the environmental impact. Assess not only the coating’s performance but also its sustainability and ecological footprint to make an informed and responsible choice.

6. Don’t Underestimate User Reviews

User testimonials offer valuable real-world insights. Dive into community forums, product reviews, and discussions to understand the experiences of others who have ventured into the realm of Raptor Liner substitutes. Learn from their successes and challenges. (See Also: Can You Powder Coat an Engine Block? Exploring Pros, Cons, and Expert Tips)

7. Invest in Quality Tools

High-quality application tools can make a substantial difference in the outcome of your coating project. Whether it’s brushes, rollers, or spray equipment, invest in tools that ensure even application and smooth finishes.

8. Explore Complementary Products

Enhance the performance of your chosen substitute by exploring complementary products. Rust inhibitors, adhesion promoters, and primers can contribute to a more robust and enduring coating system.

9. Embrace Continuous Learning

The world of protective coatings is dynamic, with innovations and new products continually emerging. Stay updated on industry trends, new formulations, and application techniques through continuous learning. Attend workshops, read industry publications, and engage with fellow enthusiasts to stay informed.

10. Seek Professional Advice

When in doubt, seek advice from professionals in the field. Coating specialists and professionals can provide personalized guidance based on your specific project requirements. Don’t hesitate to consult experts for insights tailored to your unique needs.

Armed with these expert tips, you can approach the world of Raptor Liner substitutes with confidence and precision. Remember, the key lies in a combination of knowledge, experimentation, and a passion for achieving exceptional results.

FAQs: Decoding the Mysteries of Raptor Liner Hardener Substitutes

1. Can I Use Any Polyurethane Hardener as a Substitute for Raptor Liner?

Yes, in some cases. However, it’s crucial to ensure compatibility. Always conduct compatibility tests to avoid adverse reactions and ensure optimal performance.

2. How Do I Know if a Substitute is Compatible with the Original Raptor Liner?

Thoroughly research the composition of both products and, most importantly, conduct compatibility tests on a small, inconspicuous area. This helps prevent any unexpected issues during the application.

3. Are DIY Substitutes as Effective as Commercial Products?

It depends on the specific substitute and the application. Some DIY alternatives, like epoxy resin blends, can offer excellent results, while others may fall short. User reviews and testing play a crucial role in determining effectiveness.

4. Can I Mix Different Coating Brands and Products for Custom Solutions?

While some coatings may be compatible, it’s generally advisable to stick to products within the same brand or product line. Mixing different brands may lead to compatibility issues and compromise the coating’s performance.

5. Are Linseed Oil-Based Coatings Durable Enough for Automotive Applications?

Linseed oil-based coatings can provide a protective layer, but their durability may vary. Consider the specific application and environmental factors. They may be more suitable for less demanding projects. (See Also: Can You Paint Suspension Parts? A Guide to DIY Suspension Makeovers)

6. What Precautions Should I Take When Using Raptor Liner Substitutes?

Follow all safety guidelines provided by the manufacturer of the substitute. Wear appropriate protective gear, work in a well-ventilated area, and take necessary precautions to avoid skin contact or inhalation of fumes.

7. How Long Does It Take for Raptor Liner Substitutes to Cure?

Curing times vary based on the substitute. Follow the manufacturer’s recommendations for specific curing durations. Factors such as temperature and humidity can also influence curing times.

8. Can I Apply Raptor Liner Substitutes Over Existing Coatings?

In some cases, yes. However, proper surface preparation is crucial. Ensure the existing coating is clean, smooth, and well-adhered. Sanding or stripping may be necessary for optimal adhesion.

9. What Should I Do If I Encounter Compatibility Issues Mid-Application?

Stop the application immediately. If you notice any compatibility issues, such as bubbling or uneven drying, consult the product’s technical support or customer service for guidance on how to rectify the problem.

10. Are Raptor Liner Substitutes Suitable for Marine Applications?

It depends on the substitute. Some coatings may offer water-resistant properties, making them suitable for marine use. Consider the specific substitute’s features and check with the manufacturer for marine application recommendations.

Navigating the intricacies of Raptor Liner hardener substitutes requires careful consideration and a good understanding of the products involved. By addressing these frequently asked questions, we aim to equip you with the knowledge needed to make informed decisions and achieve successful coating projects.

Conclusion: Navigating the Coating Landscape

As we conclude our expedition into the realm of protective coatings, remember that the pursuit of a Raptor Liner hardener substitute is a journey filled with possibilities. The perfect substitute may be just around the corner, waiting to exceed your expectations. Arm yourself with knowledge, experiment with alternatives, and embark on your coating endeavors with confidence and expertise. In the dynamic world of protective coatings, innovation and exploration pave the way for new horizons.